game

From Zero to Retail Hero – Your First Week in Discounty

Starting Discounty feels overwhelming. You ve got [ ]

Technology

U4GM Diablo 4 Items: Browse Lair Boss Keys, Runes, Elixirs & More

Diablo 4 is an action game in which players need to kil [ ]

Technology

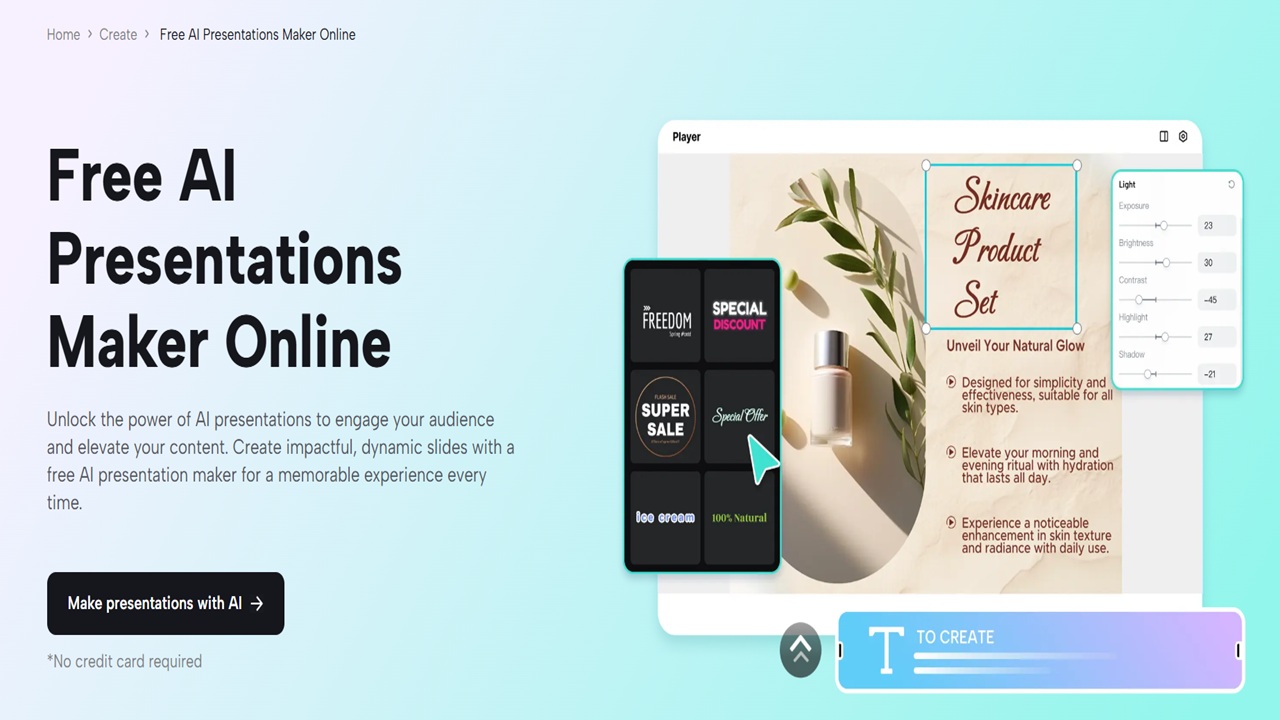

How Pippit’s AI Presentation Maker is Revolutionizing Business Pitches in 2025

The year 2025 brings a complete transformation to how b [ ]

Technology

Win Full-Bright Scholarship With Gauth Personal Statement Writer

It is the dream of any student to successfully apply fo [ ]

Lifestyle

Ferrero Rocher Bulk – Navigating Minimum Order Quantities & Pricing

Beyond mere pleasure, Ferrero Rocher s attraction [ ]

Business

Selecting Raw Materials for Supplement Manufacturing

The quality and efficacy of a dietary supplement hinge [ ]

Lifestyle

Creating Gothic Art Descriptions Made Easy with Gauth

Gothic art is very detailed and has strong contrasts an [ ]

Technology

Enlisting the Possible Causes of Compressed Air Leakage

The most common issue in most compressed air systems is [ ]

Technology

Future Trends in Hot Die Forging: What to Expect

Hot die forging has long been a cornerstone in the manu [ ]

Technology

Visit the Homepage for Obtaining Details about the Forging Process

The vast majority of metals can be produced and fabrica [ ]

Technology

The Future of Fiber Optics and Its Endless Possibilities for Connectivity

Technology is continuously evolving, and the future loo [ ]

Technology

Get The Detail About the Best Case Making Manufacturers In The Market!

The Internet has developed so much that the work that n [ ]